Understanding Our XLR Cable Series

When designing an XLR, making sure the cable contains the right features to limit the amount of electromagnetic interference (EMI) and noise is key. EMI will result in static or poor signal performance so it’s best to take all the steps necessary to keep it from interrupting your connection.

OVERVIEW

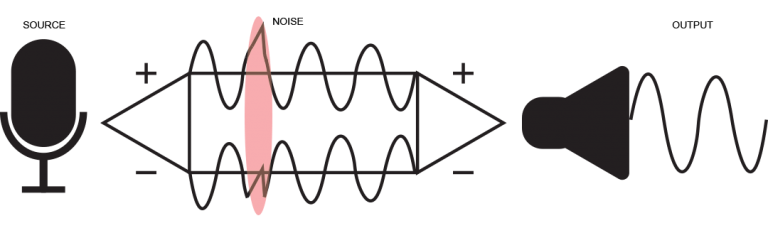

In a balanced cable, there are 2 conductors for the balanced signal and 1 conductor for the ground return path. An identical signal is sent to both signal conductors, with one of the signals inverted. If you picture the signal traveling through the conductor as a sine wave, the peaks of the normal conductor’s signal line up with the valleys of the inverted conductor’s signal. The conductors are twisted around each other in a twisted pair configuration so they maintain the closest spacing possible to ensure that if external noise affects them, the noise affects both conductors equally. When two identical signals with an inverted phase relationship like this interact, any noise that has interacted with the cable is effectively canceled out once the one signal is re-inverted back to its normal phase at the end of the cable, matching the other conductor’s signal. This is standard balancing. There is something known as quasi-balancing as well that allows for the same process to happen but without the need for an identical signal going through both conductors. The non-used conductor just acts as a noise cancellation tool for the cable.

Since noise and interference are commonplace in a digital world, insulation, shiedling, and the conductors themselves all assist the cable in its effectiveness to minimize the impact of interference.

INSULATION

Insulation is a crucial part of the XLR as it acts as a barrier between the conductors. While it’s important to have the conductors close to each other to help the balancing process, the insulation prevents electrical leakage. It also affects capacitance and improves the dielectric properties of the cable. One of those dielectric properties is the dielectric strength which is how well the material between the conductors stops the flow of electricity. So a higher dielectric strength means that less current is leaking between conductors which can help preserve signal integrity. The type of insulation can also withstand high temperatures so when you are soldering connectors to the end of the cable or making repairs, the insulation does not immediately melt.

SHIEDLING

A shield covers all the conductors and insulation in a cable and acts as an electromagnetic barrier between the conductors and the outer cable jacketing. There are various types of shields, for example, spiral shielding, braided shielding, and aluminum foil. The shield can affect the flexibility of the cable as well as how well it responds to interference. An aluminum foil shield is the most effective at stopping interference from affecting a signal but it is the most inflexible shield. The spiral shield is the most flexible shield but it is unable to fully stop all interference due to the gaps in the spiral that occur when the cable is bent. The shielding also helps prevent crosstalk, which is when a cable picks up signals from other nearby cables or devices. When crosstalk happens in a cable, it can lead to unwanted interference (e.g. static or buzzing).

CONDUCTORS

The conductors also make a difference in how a cable handles signal transmission. The thicker the wire gauge, the less resistance the signal will encounter. But as a trade off, the thicker the wire gauge, the cable will become less flexible. Stranded conductors are made up of several copper strands that are wrapped around each other to make a single conductor whereas a solid conductor is one solid piece of copper that makes a single conductor. Stranded conductors are much more flexible and reliable than solid so they tend to be the more popular choice for XLR cables.

We know that equipment requirements change and your gear has to adapt, which is why we designed three tiers of XLR cables to accommodate your needs.

PERFORMANCE SERIES

Our Performance Series XLRs are perfect for live sound events where constant stress is put onto your cables. The cable is made using two stranded 24 AWG conductors wrapped in a polyethylene (PE) insulation. It also features a single spiral copper shield which allows the cable to remain very flexible to make it easy on stagehands who need to wrap and unwrap the XLRs quickly and frequently.

PROFESSIONAL SERIES

Our Professional Series XLRs are a step up from our Performance Series for live sound events. The cable is made using two stranded 23 AWG conductors. The conductors are wrapped in a cross-linked polyethylene (XLPE) insulation and the cable features a single braided, tinned copper shield which provides even more protection from EMI and noise than standard spiral shields. The slightly larger conductors and improved shield make it a less flexible option than the Performance Series but better at preserving signal integrity, while still being flexible enough for stage use.

PREMIUM SERIES

The Premium Series XLR cables are designed for environments where a pristine signal is required. The XLR is made using four stranded 24 AWG conductors. The dual conductor configuration, also known as a star quad configuration, assists in the balancing process as the signal is traveling through the cable as it doubles the noise cancellation. The conductors are wrapped with a low-density polyethylene (LDPE) insulation and the cable features one tinned copper braided shield and one bare copper braided shield. This dual shield design improves EMI resistance by eliminating any gaps in the shielding that can weaken its effect. On top of the PVC jacketing of the cable is a black nylon braided sleeve for added durability and aesthetic. This is the least flexible of the three cables as the four conductors and double shield don’t allow for excessive movement. The Premium Series is ideal for use in studio recording applications and Hi-Fi systems. It would not be a great choice for live sound settings.

CONNECTORS

No matter what level of cable you need, all of our XLR series feature the same superior Io Audio Technologies XLR connectors. The connectors feature durable die-cast zinc shells with built-in latch locks to provide a reliable connection when mated with equipment. They also feature a plastic insert that tightens onto the cable to provide strain relief while an additional rubber boot delivers extended support from excessive bending. Finally, the silver-plated contacts ensure a perfect signal every time.

To learn more about these three cables, view our XLR comparison document to compare all their specifications in one place.